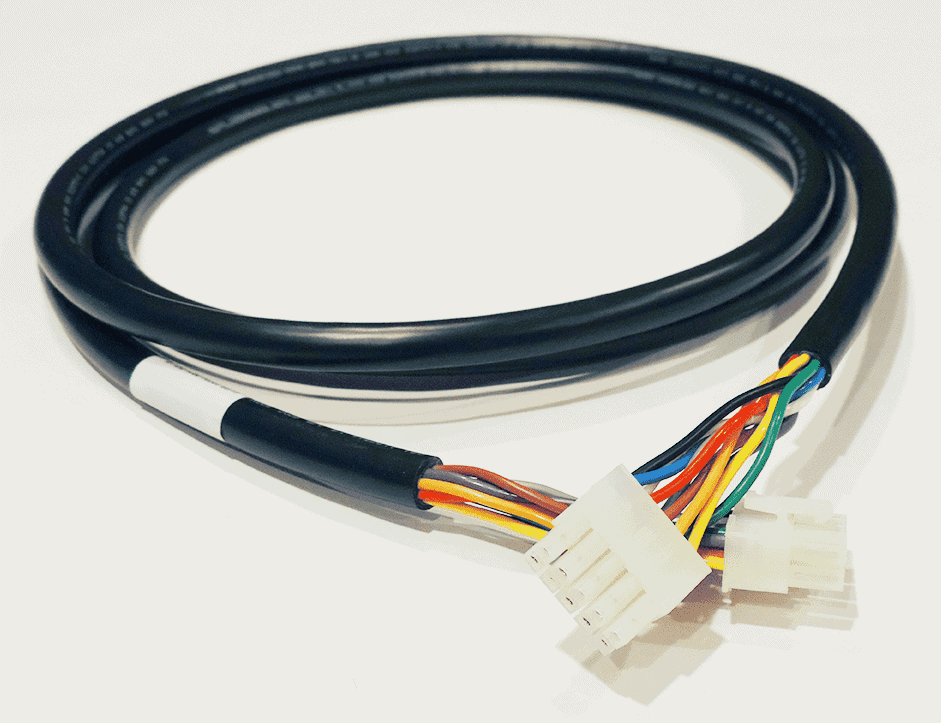

Cable assemblies enclose vulnerable wiring in protective sheaths and incorporate a nearly unlimited variety of connectors based on the intended use. Overmolded cable assemblies go a step beyond a simple sheath by enclosing the cable or wire and connector with overmolded material.

Cable or wire assemblies are placed within a mold, which is then injected with a pressurized molten plastic. Once the material hardens, it turns into a protective layer that seals the junction between the wires/cable and connectors to reduce the risk of damage.

Why Customize?

Customizing your overmolded cable assemblies is the best option for ensuring your electronics are protected. They are ultimately more rugged and cost-effective because the assemblies are seamless and essentially turned into just one comprehensive piece. The overmolding process allows customization of the following:

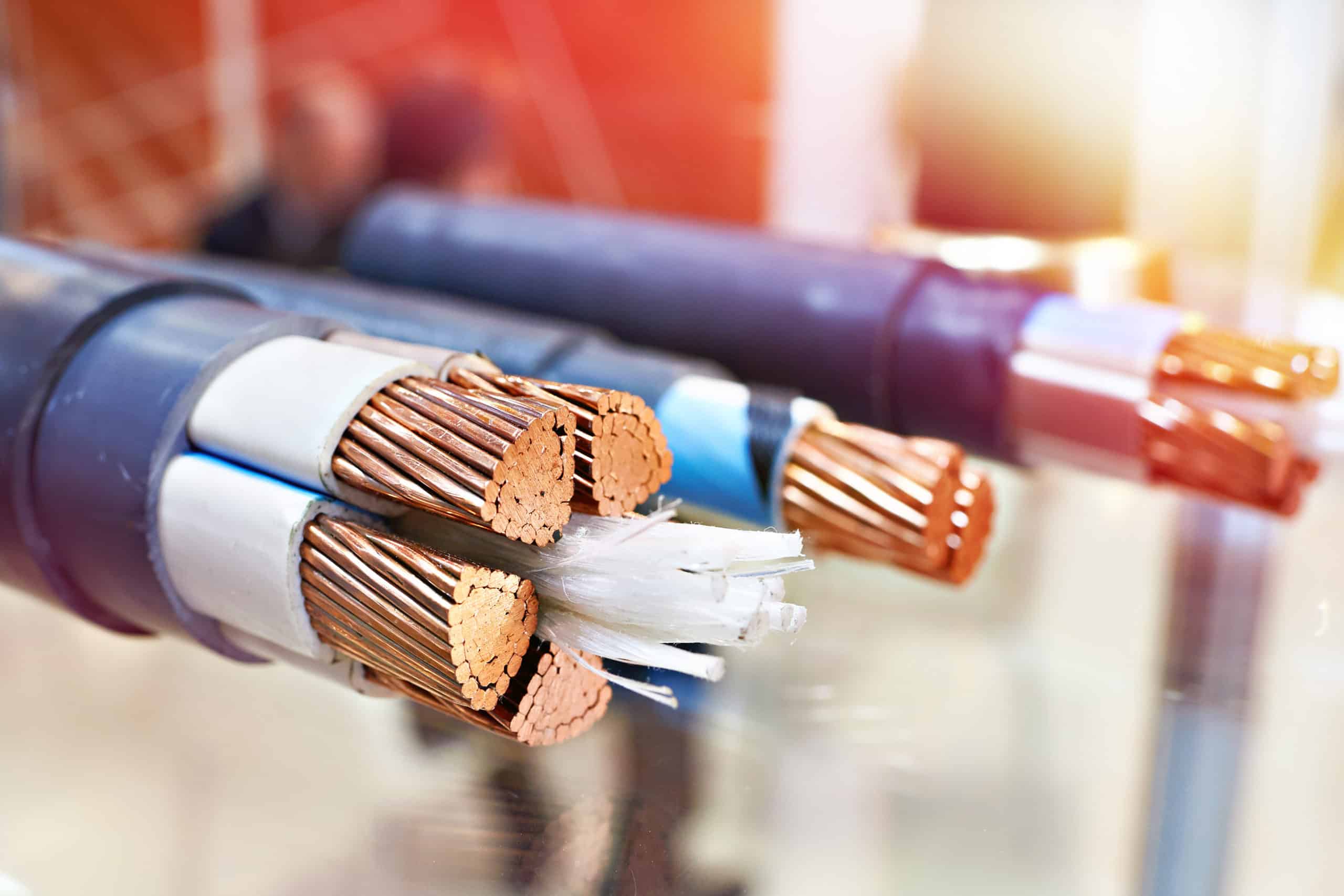

- Overmold materials. Different materials imbue the assembly with different degrees of chemical or moisture resistance, heat resistance, and more. There are a variety of common plastics available for overmolding. Polyvinyl chloride (PVC) is an inexpensive general solution, but only offers minimal protection against strong acidic chemicals. Conversely, polyethylene (PE) and thermoplastic elastomer (TPE) can withstand strong acids. Polyurethane (PU) and thermoplastic polyurethane (TPU feature good resistance to weather, aging, and other harsh environmental conditions, making them ideal for outdoor applications. Material selection is based on degrees of protection desired and compatibility with wire insulation or jacket materials.

- Color. During custom projects, manufacturers can add distinct colors and resins to the molten plastic. These colors can be used to match a company’s branding, color code the assembly according to instructions or regulations, or make the equipment more aesthetically pleasing. Custom colors can improve safety and organization, as well as increase the marketability of a product.

- Environmental suitability. Overmolded assemblies can be built with unique features and molded layers to protect the wires against any extreme levels of wear, stress, and abrasion that may be expected in the intended operating environment.

- Regulatory compliance. Some industries maintain specific regulations regarding required levels of protection for wiring and cable assemblies. Custom overmolding processes can be customized for compliance with a variety of quality standards including IPC/WHMA-A-620 and RoHS.

Customized Overmolded Cable Assembly Applications

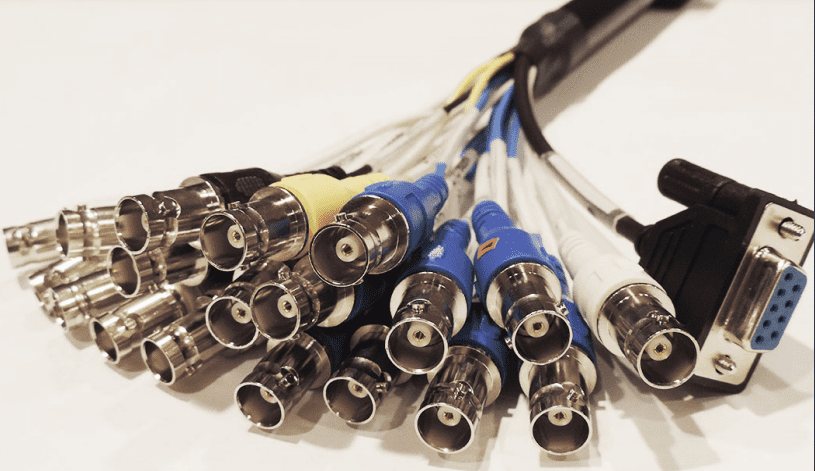

Custom overmolded assemblies offer enhanced strain relief and suitability for a wide range of environments. They can outlast units with multiple separate parts or thin layers of protective sheathing. Custom colors also make them ideal for complex installations or environments where visibility is poor. We’re proud to serve the following industries:

- Automotive. Automotive assemblies must withstand the harsh heated environments inside vehicles, exposure to dust, and contact with chemicals.

Communications. Communication wiring needs to be able to withstand harsh environmental conditions to ensure stable performance. - Home electronics. Wiring for consumers needs to be able to withstand a lot of flexing and adjustment and organizational coloring strategies make DIY installations and assemblies more appealing.

- Medical equipment. Wiring for medical equipment and tools need to be able to withstand constant flexing and wear. They also need to be able to withstand continuous sanitation efforts to make them compliant with hygienic standards in hospitals.

- Military and defense. Custom overmolded assemblies can withstand harsh conditions and extreme weather, use in a variety of different environments, and constant flexing. They offer an ideal solution for equipment which must operate reliably in harsh and dangerous environments in a variety of situations.

- Oil and gas. Oil and gas industrial facilities, both in the processing plant and on the oil field, rely on cable assemblies for machinery and equipment that operate effectively near chemicals and constant wear and tear from harsh environmental factors.

- Wind and solar energy. Alternative energy systems need robust wiring systems that remain durable in interior and exterior environments.

- Industrial and OEM. Overmolded wire and cable assemblies are ideal for the harsh conditions found in industrial environments.

Consolidated Electronic Wire & Cable Solutions

When you choose custom overmolded cable assemblies, you get more than custom designs and colors. This process ensures you have a cable assembly that’s the right fit for the electronics, the environment, and the relevant regulatory standards of your operation. At Consolidated Electronic Wire & Cable Solutions, our team uses high-performance materials and expertly designed systems to create assemblies that outperform and outlast other assemblies.

Contact us today for more information about our overmolding capabilities.

() Quote Cart

() Quote Cart

Comments are closed