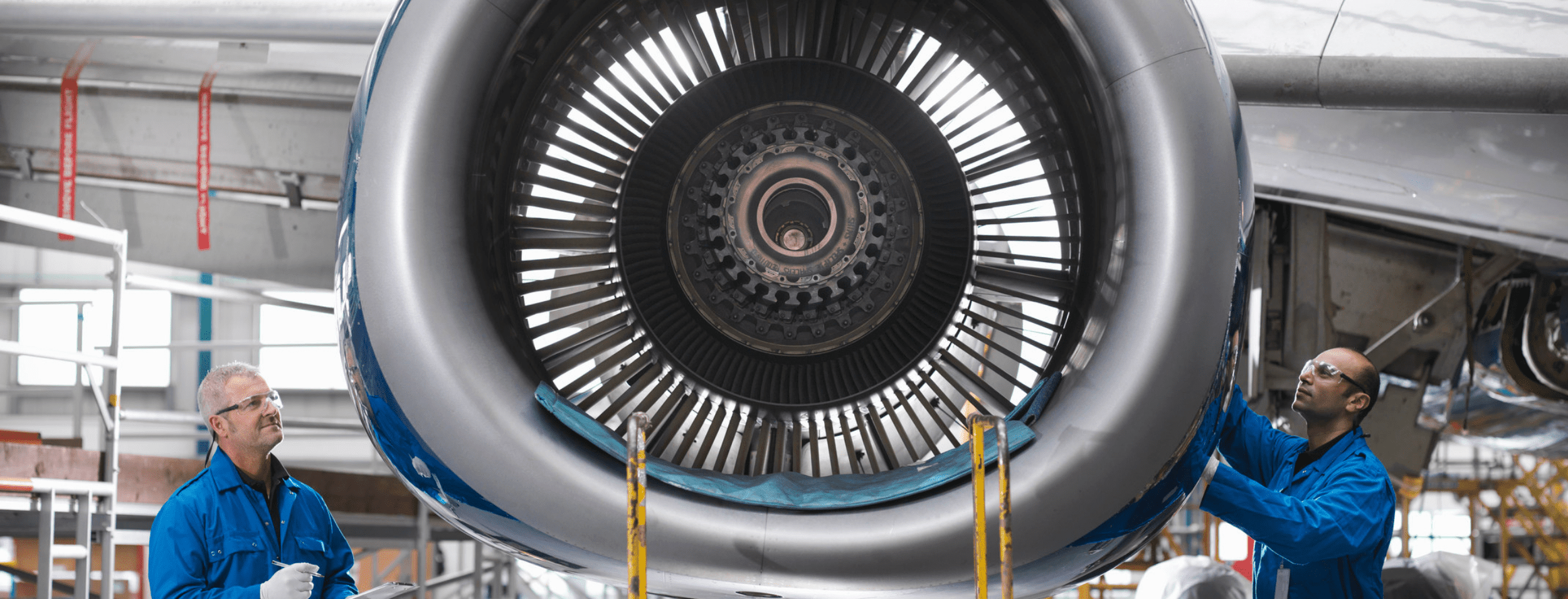

Military and aerospace applications require exceptionally reliable electrical wiring and cable assemblies for safe and dependable equipment operation in no-fail applications. While standard cable and wire configurations are sufficient for many everyday systems, the extreme conditions present in military and aerospace applications require a higher degree of quality and reliability.

For this reason, military and aerospace cable assemblies and wire harnesses are subject to extremely rigorous quality standards and regulations. At Consolidated Electronic Wire and Cable, we have the knowledge and experience necessary to meet even the most stringent requirements for everything from tactical cable to military-grade connectors and space equipment cables.

Industry Challenges

Military and aerospace applications require extremely dependable electrical systems, as they are often required to operate in harsh conditions for long periods of time without the opportunity for extensive repairs or adjustments. The four major challenges facing military and aerospace operations are reliability, strength, operating environments, and complexity.

Quality and Reliability

In military and aerospace operations, a component or system failure can place the entire crew at risk, so it is crucial that systems operate with an exceptional degree of reliability. To this end, aerospace and military cable assemblies must meet stringent quality control specifications.

For products ranging from aerospace cable assemblies to military connectors, every electrical component used in these industries is subject to rigorous testing. Testing of components is largely determined by the intended application, and can include testing for high pressures, extreme temperatures, corrosive substances, high voltage, contact force, vibration, and a variety of other potentially compromising conditions.

Strength and Durability

Military and aerospace industry standards require that cables and wire harnesses exhibit an exceptionally high degree of strength and durability. One failed component can result in catastrophic failure and place the lives of soldiers, crews, and operators at risk, so it is particularly important that military and aerospace cables, wires, and connectors be able to withstand high pressures, impacts, extreme vibration, wear, and abrasion at levels well above what might damage more standard types of electrical equipment.

Extreme Environments

Aerospace and military equipment must be able to operate reliably in some of the most extreme environments known to man.

- Military vehicles may be used in extreme heat and desert climates with abrasive sand and dust, or in aquatic applications where they must contend with corrosive seawater, cold temperatures, and high pressure.

- Aerospace equipment must be able to operate reliably at high altitudes and outer space, where extreme temperatures, lack of oxygen, and radiation exposure create highly volatile conditions.

To counteract the effects of these extreme environments, aerospace and Mil-Spec cable assemblies and wire harnesses are designed and manufactured from materials that are resistant to broad temperature fluctuations, corrosion, abrasion, radiation, and other factors that could limit operational reliability.

Application Complexity

By their nature, military and aerospace applications tend to feature unique operating factors or other circumstances that will cause standard equipment to underperform. For example, a standard wire harness used in an automobile will likely fail in a military vehicle that must be able to continue functioning in all types of weather, terrain, and combat conditions. Developing solutions to specific application complexities requires an experienced manufacturer that understands all of the available materials, options, and technologies, and how they can be used to optimize performance and grant specific properties.

Our team at Consolidated Electronic Wire & Cable specializes in customizing wire harnesses, cable assemblies, and other electronics solutions for use in even the most complex situations. Examples of wire and cable solutions for use in some extremely complex environments, include:

- Cockpit control modules for fighter jet instruments

- Addressing launch sequence technicalities used for Space Force rockets

- Night vision goggles and communications equipment used by ground troops

Applications

Aerospace and military cables and wire assemblies facilitate safe and dependable operation for a number of critical applications, including:

- Military ground equipment

- Field and inter-shelter communication equipment

- Airborne communication and navigation systems

- Remote weapons control

- Ships, submersibles, and other marine systems

- Satellites and space shuttles

- Avionics systems

- EMI sensitive equipment

- Space Force systems

As new technology continues to expand military and aerospace capabilities, Consolidated Electronic Wire & Cable remains at the forefront of electrical system development and innovation.

Learn About Our Military & Aerospace Solutions

For over a century, Consolidated Electronic Wire & Cable has been a leading provider of quality wire and cable assemblies for customers spanning a wide range of industries. With extensive experience developing highly specialized, no-fail electrical assemblies for critical applications, we are committed to meeting stringent industry standards for our customers in the military and aerospace sectors. Whether you need rugged Mil-Spec cable assemblies or highly complex aerospace wire harnesses, we have the experience and manufacturing technology to design and fabricate your electrical systems with the utmost precision and reliability.

To learn how our military and aerospace electronic solutions can improve your next project, request a quote today.

() Quote Cart

() Quote Cart