Enclosed electronics, such as vehicle systems, appliances, control panels, and electronic meters contain hook-up wire to deliver power to and between various components. Hook-up wire is low-voltage, low-current wire with a single copper conductor covered with insulating material. It is also referred to as insulated wire, lead wire, single-core insulated cable, or electronic wire.

Consolidated Electronic Wire & Cable has over 100 years of experience providing hook-up and lead wire solutions to customers in many industries. Learn more about what hook-up wire is, the different types, and the benefits it has for many applications.

What is Hook-Up Wire?

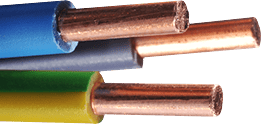

Hook-up wire is typically used in low-voltage (i.e., 600V or less), low-current, enclosed electronic systems. It has a single copper conductor, which can be a solid strand or a bundle of thin strands. Insulating materials including PTFE, PVC, neoprene, silicone, or rubber surround the core.

Selecting the Right Hook-Up Wire for Your Application

It’s important to select a hook-up wire that’s rated for the voltage, amperage, and wattage of the application. The setting or environment, such as indoor, outdoor, highly corrosive, or marine, is another critical consideration.

We offer several different types of hook-up wire:

Types of Hook-Up Wire

Hook-Up Wire Benefits

Hook-up wire is useful in such a wide range of applications because it is available in many configurations for specific needs. Some of the benefits of hook-up wire are:

- Electrical Conductivity. Copper cores have exceptional conductivity for reliable performance and efficient power transfer.

- Flexibility and Maneuverability. Hook-up wire can be made with a single, solid core or a bundle of thin cores, which makes them suitable for exterior use, confined or small space installation, and other places where installation is a challenge.

- Durability and Long Service Life. Hook-up wire is resistant to wear and tear, and can be insulated and jacketed with a range of high-performance materials for longevity.

- Temperature and Chemical Resistance. Hook-up wire provides safe operation in harsh indoor and outdoor climates and environments with high temperatures and corrosion.

Interested in a Custom Wire or Cable Solution?

Contact our team of experts to learn more about our broad range of custom capabilities.

Speak to an expert Explore Our Custom CapabilitiesConsolidated, Your Trusted Hook-Up & Lead Wire Manufacturer

Understanding the types of hook-up and lead wire available and their use cases helps you select the best wire for your needs. Consolidated Electronic Wire & Cable offers UL-style, high-temperature, MIL-Spec, building and fixture, and automotive hook-up wire options in a range of sizes, ampacities, and insulating materials. Our extensive selection of wire and value-added services provide a one-stop shopping solution for standard and custom wiring needs.

Ready to Discuss Your Project? Speak With a Wire & Cable Specialist Today

If you are ready to take the next step or discuss your wiring project with an expert, contact us or request a quote today.

() Quote Cart

() Quote Cart