Consolidated Electronic Wire & Cable offers RoHS- and UL-compliant multi-pair cable for a variety of applications.

Cable is available from 16 to 28 gauge, in single and multi-pair, jacketed and unjacketed constructions, and spool sizes from 100 feet to 1000 feet, as well as on larger bulk reels.

Single pair unshielded is available in 18 to 24 AWG, while multi-pair foil shielded cable is available from 18 to 28 AWG. All cables feature annealed solid or stranded tinned copper wire, and color coded insulation in a variety of temperature ranges.

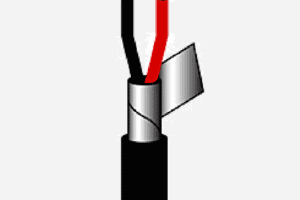

Individually shielded Multi-pair cable is also available with a high density black polyethylene jacket, which is designed for direct burial.

It features individually shielded pairs, and a 100% Mylar/aluminum foil shield with 25% overlap. The 20 AWG cable, the 20 AWG cable is available on 100 ft to 1000 ft or large bulk reels.

The Versatility of Multi-Pair Cable

Since the invention of the telephone in the late 1800s, twisted-pair and multi-pair cable have played a critical role in our day-to-day communications. Now strung through networks, building infrastructures, and vast underground systems, these unique cables are specially designed to guard against electromagnetic interference and crosstalk.

Similar in many ways to multi-conductor cable, this specialty wiring is particularly popular in the computer and telecommunications industries.

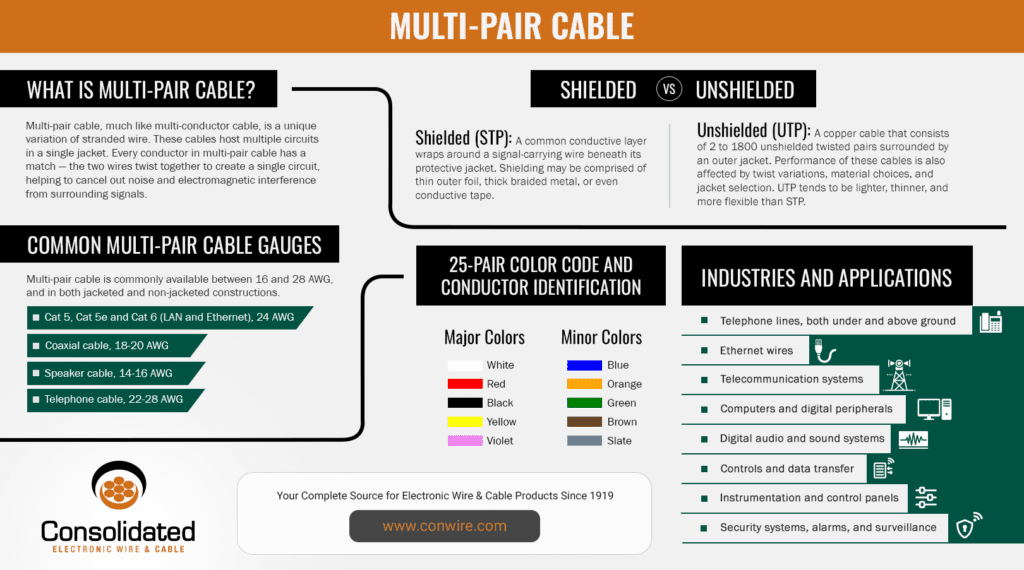

What is Multi-Pair Cable?

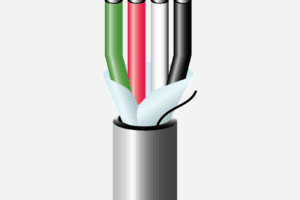

Multi-pair cable, much like multi-conductor cable, is a unique variation of stranded wire. These cables host multiple circuits in a single jacket. Unlike in a standard multi-conductor cable, however, every conductor in multi-pair cable has a match — the two wires twist together to create a single circuit, helping to cancel out noise and electromagnetic interference from surrounding signals.

Click Image to Enlarge

Invented in 1881 by Alexander Graham Bell, twisted-pair cabling solved one of the greatest challenges of early telegraph and telephone lines: Electric trams, electric power distribution, and the growing popularity of both electrical power and communications created disruptive noise and interference in utility circuits.

By twisting two wires carrying equal and opposite signals into a pair, noise is balanced and eventually canceled out at the receiver in every individual circuit, and thus in the system as a whole.

Shielded and Unshielded

Commonly abbreviated as STP (Shielded Twisted Pair) or UTP (Unshielded Twisted Pair), both styles of multi-pair cable have the same purpose: reliable connectivity, specifically for electronics and communications.

In the construction of any shielded cable, whether paired or not, a common conductive layer wraps around a signal-carrying wire beneath its protective jacket. Shielding may be comprised of thin outer foil, thick braided metal, or even conductive tape. This creates a Faraday cage, and the resulting electromagnetic shield helps to minimize noise and interferences, maintaining signal clarity and reducing radiation output.

Depending on the material used and its thickness, frequency, and grounding, STP cable can dramatically enhance effective cable and network management. However, STP cable can present additional installation challenges: Thick shielding makes a cable heavier, thicker, and more difficult to handle, while thin shielding can be delicate and easily torn.

In contrast, unshielded cable relies purely upon electromagnetic balancing and filtering via media filters or baluns. The performance of these cables is also affected, of course, by twist variations, material choices, and jacket selection. UTP tends to be lighter, thinner, and more flexible than STP.

Safety Ratings: Plenum and Non-Plenum Cable

Network cables — whether for security, telecommunications, data, or otherwise — run throughout an entire building’s infrastructure, and can therefore create ideal pathways for fire.

Fortunately, sophisticated jacket and insulation materials allow multi-pair cable to operate safely, no matter their style of installation. The most significant distinction in their construction is between plenum and non-plenum cabling.

Riser cable, also known as non-plenum cable, are designed to be run between floors and through open shoots in non-plenum building areas. They tend to have a high tensile strength in order to support the weight of hanging or stretching in open space.

Plenum cable, outfitted with jackets and insulation specially designed to withstand extreme temperatures and offer low-smoke performance, is rated to run through HVAC system areas and the confined plenum spaces in buildings. These materials are held to rigorous fire safety standards these materials; look for jackets made of PVC or FEP.

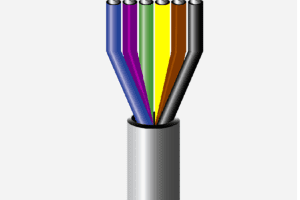

The 25-Pair Color Code and Conductor Identification

An extremely helpful identification guide in the telecommunications industry, the 25-pair color code assigns specific color combinations to the jackets (or insulation) of individual conductors in a multi-pair cable.

The first (also known as “major”) color comes from one group of five colors, and the second (or “minor”) color is selected from a separate five-color group. The major colors, in order, are:

- White

- Red

- Black

- Yellow

- Violet

The minor colors, in order, are:

- Blue

- Orange

- Green

- Brown

- Slate

The white group, or the first five color combinations (white/blue, white/orange, white/green, white/brown, white/slate) are the most commonly used in telecommunications and data wiring worldwide, and are therefore the most consistent for easy identification.

The names of the colors correspond with particular shades and match with the electronic color code (the code features the same ten colors, though ordered differently). Colored stripes, dots, rings, and even Mylar ribbons can help technicians trace the wire colors — and therefore the wires themselves — in complex network configurations.

Common Multi-Pair Cable Gauges

Multi-pair cable is commonly available between 16 and 28 AWG (American Wire Gauge), and in both jacketed and non-jacketed constructions. Gauges for common applications include:

- Cat 5, Cat 5e and Cat 6 (LAN and Ethernet), 24 AWG

- Coaxial cable, 18-20 AWG

- Speaker cable, 14-16 AWG

- Telephone cable, 22-28 AWG

Gauging these specialty cables by the naked eye can be deceptive — jacket thicknesses, shielding, and insulation, let alone the number of pairs, all take up significantly more space than a single, solid wire. For the cable’s gauge measurement, only the sums of each conductive wire’s cross-sectional area are taken into account — not its overall physical size.

Industries and Applications

Multi-pair cable is critical to telecommunications, electronics, and networks of all sizes in a wide range of applications. It can be found in offices, equipment, and infrastructure, carrying signals and data of all kinds, including:

- Telephone lines, both under and above ground

- Ethernet wires

- Telecommunication systems

- Computers and digital peripherals

- Digital audio and sound systems

- Controls and data transfer

- Instrumentation and control panels

- Security systems, alarms, and surveillance

Learn More

Consolidated Electronic Wire and Cable has been an industry leader in custom cable solutions for nearly 100 years. Our team delivers for projects both large and small across a wide range of industries for various applications, including multi-pair cable arrangements. To learn more about our custom cable solutions and how we can help with your next project, reach out to us today.

[/expand]

() Quote Cart

() Quote Cart