With so many different types of cables on the market, it can be a challenge to find the perfect cable for your application. With some knowledge of your application’s demands, however, you can quickly narrow down your options and find the ideal solution for you company. To simplify your search, we’ve covered some of the key aspects to consider before investing in a cable.

Cable Use

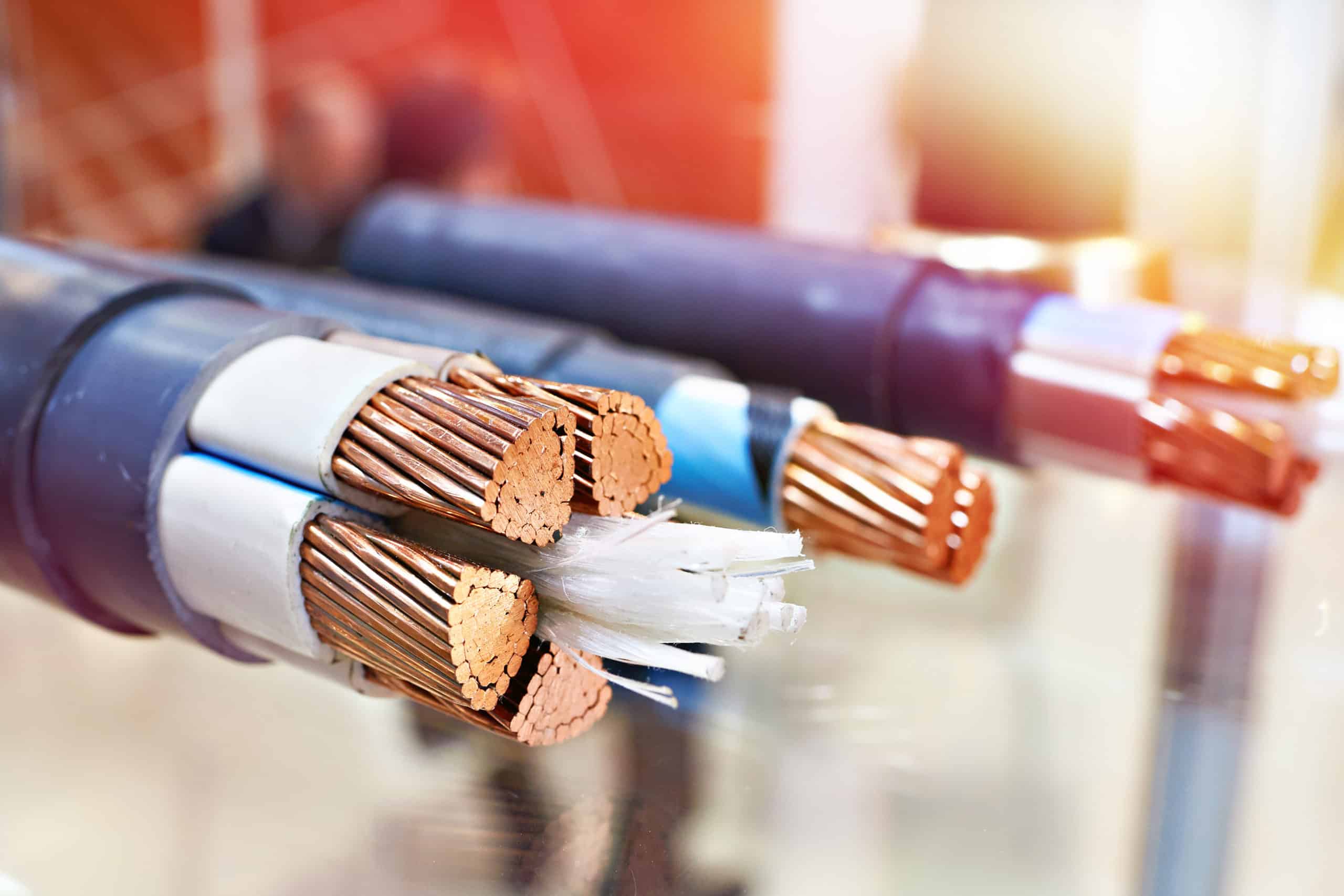

How you plan to use your cable will determine how many conductors you’ll need within it. Depending on their use, cables can contain as few as one conductor to as many as 100. These conductors are available in a variety of combinations, gauges, and building materials, all of which are better suited to certain applications. Tinned cooper wire, for example, is an excellent choice for cables located outside because of its high resistance to oxidation. Similarly, silver plated copper wire works well in particularly hot climates because of its corrosion resistance.- Weather

All cables require proper insulation against typical atmospheric conditions, including temperature, moisture, and air pressure. A qualified manufacturer like Consolidated Wire can provide you with an appropriate material for your application. Some of our most popular and versatile materials include:

- Polyvinyl chloride (PVC), an inexpensive and easy-to-use insulator that resists flames, abrasion, moisture, gasoline, acids, solvents, and ozone

- Semi-rigid PVC, a strong insulator against acid, water, heat, and alkalis

- Polyethylene, an inexpensive plastic known for its strong electric qualities and resistance to soldering, solvents, cutting, and cracking

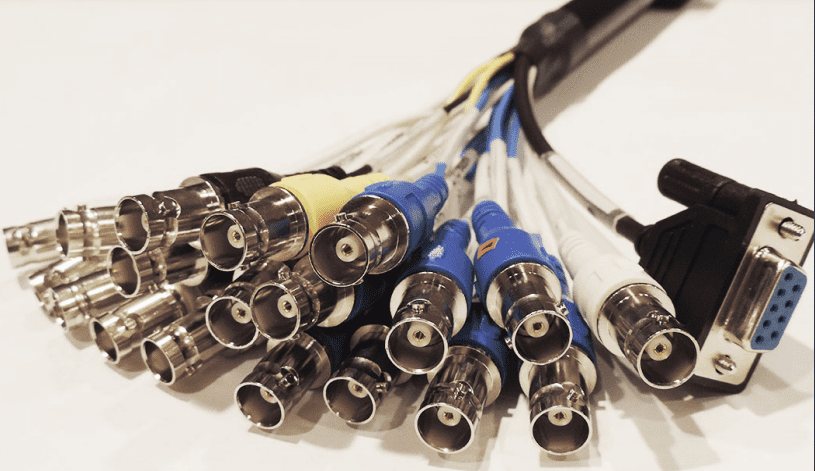

- Flexibility

A cable can be more or less flexible depending on its typical movements over the course of the day. Most wires are available in normal, flexible, or robotic-flexible versions. The type of jacketing chosen for your cables can also have an effect on their flexibility. Polyurethane jacketing, for example, provides a much higher level of strength and flexibility than other materials. - Indoor/Outdoor Use

Outdoor cables generally require greater protection from the elements than their indoor counterparts. A number of jacketing materials can afford the necessary level of protection. Consolidated Wire’s PVC, Semi-Rigid PVC, and PE jacketing, for example, all provide excellent weather resistance when complemented with Carbon Blank. Our polypropylene, polyurethane, polytetrafluoroethylene jacketing offer excellent resistance to foul or extreme weather, as well.

If you have any additional questions about cables, the experts at Consolidated Wire are here to help. With more than a century of experience in developing customized wire and cable solutions, we have the expertise needed to determine which materials and components will best fit your application. Download our “Creating a Custom Cable” eBook today for a more detailed overview of cable customization.

() Quote Cart

() Quote Cart Cable Use

Cable Use

Comments are closed