At Consolidated Electronic Wire & Cable, we’ve designed and fabricated standard and custom wire and cable solutions for over 100 years. This extensive experience, combined with our broad range of services and our stringent quality assurance processes, enables us to provide high-quality products that meet some of the most unique customer specifications and strictest industry standards. For data transmission applications that require protection from electromagnetic interference, we offer custom shielded cable and wire assemblies.

What Is EMI?

The effects of EMI on an electric circuit or assembly vary from mild to severe—i.e., degradation of transmission quality to total transmission loss—all of which will have some impact on the performance of the electrical and electronic equipment. In any case, it is in the best interest of the facility to take measures to reduce the effect of EMI on its equipment.

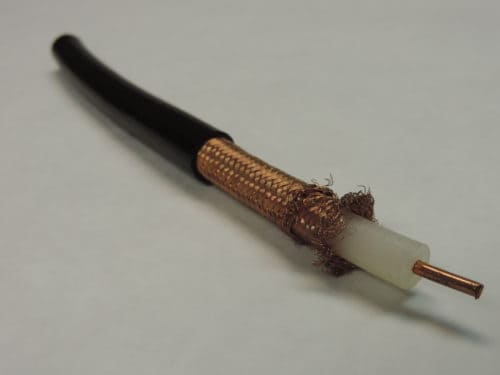

One of the most common solutions to combating EMI is integrating shielding in the wire and cable assemblies. Shielding is designed to wrap around the conductor component of wires and cables and reduce the intensity and volume of noise to minimize or eliminate the effect EMI has on transmissions.

The Importance of Cable and Wire Shielding

All electrical and electronic wires and cables pass energy to and pick up energy from their surroundings. Cable and wire shielding help prevent these actions from occurring, thereby decreasing the risk of unwanted external interference entering the system and electromagnetic energy generated within cables and wires affecting nearby sensitive components.

Types of Shielding

- Braided shielding is a woven mesh of bare or tinned copper wires. It offers between 70–95% interference coverage, depending on the tightness of the weave.

- Spiral shielding is made by wrapping conductive material helically around the core. It is generally used in small to medium cables and wires to achieve greater coverage.

- Foil shielding—also known as tape shielding—consists of a thin layer of aluminum or copper sometimes bonded to a carrier material (e.g., polyester) to improve strength and durability. It is designed to be wrapped around the cable or wire with overlap to provide 100% coverage.

The ideal EMI cable shielding solution depends on the application. For example, braided and spiral shielding is suitable for reducing EMI in low frequencies, high-coverage braided shielding is appropriate for mid-range frequencies, and foil shielding is ideal for high frequencies.

Applications of Shielded Wire and Cable Assemblies

Electromagnetic interference can significantly interrupt, obstruct, or degrade the performance of electrical and electronic equipment. As such, shielded cables and wires are beneficial in virtually every industry and industrial process that requires the use of electrical and electronic equipment. Typical applications for shielded cable and wire assemblies include:

- Data centers

- Industrial and manufacturing factories

- Medical facilities

- Military sites

- Offices

Shielded Cables and Wires From Consolidated Electronic Wire & Cable

Electromagnetic interference can affect the purity and consistency of signal transmission in cables and wires, which, in turn, disturbs or disrupts the performance of the equipment in which they are installed. Shielding help protects cable and wire assemblies from EMI, but it needs to be the right type for the interference experienced in the application environment. Whether you need braided, spiral, or foil shielding, the experts at Consolidated Electronic Wire & Cable have got you covered.

To learn more about our shielded cable and wire solutions, contact us today.

() Quote Cart

() Quote Cart