The custom cable manufacturing process consists of four main stages:

Cable Assembly Manufacturer for All Industries

From Design to Deployment: Your Custom Cable Assembly Partner. Engineered for Performance, Built for Your Needs.

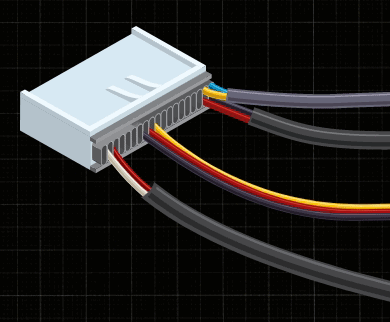

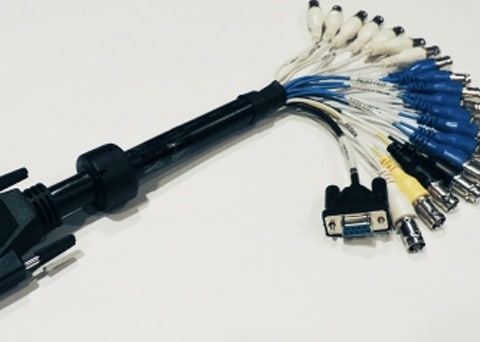

Consolidated Electronic Wire & Cable is an experienced designer and fabricator of standard and custom wire and cable solutions. We provide products that serve a critical role in various industrial, commercial, and residential applications by enabling the transmission of data and power in and between connected devices and systems. For example, our cable assemblies are carefully engineered to organize groups of cables into a single unit to facilitate installation, replacement, and maintenance in commercial and consumer enterprises. We craft them with insert molding, overmolding, custom in-housing tooling, and manual assembly.

Consolidated Electronic Wire & Cable, Your Trusted Cable Assembly Manufacturer

At Consolidated Electronic Wire & Cable, we offer a range of in-house capabilities, ranging from design and modeling to manufacturing, assembly, and testing. Our specific capabilities include:

- Cut and Shrink Tubing

- In-line Engineering

- Molding and Overmolding

- Testing and Quality Assurance

- Tinning and Soldering

- Ultrasonic Welding

- Wire Crimping and Braiding

Our Cable Assembly Solutions

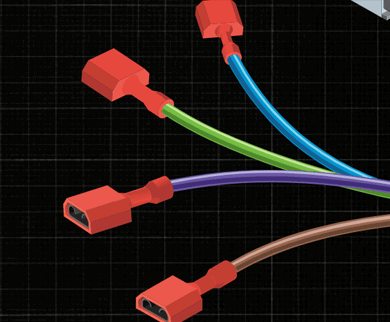

Consolidated Electronic Wire & Cable offers various cable assembly solutions. Our capabilities include designing and manufacturing custom cable assemblies to meet the unique requirements of our clients. We can also tailor the individual cables used in cable assemblies, with regard to the following:

- Cable configuration (single-conductor, multi-conductor, multi-paired)

- Electrical properties (voltage rating, amperage rating, capacitance rating)

- Operating temperatures

- Flexibility

- Environmental rating (indoor vs. outdoor)

- Regulation compliance

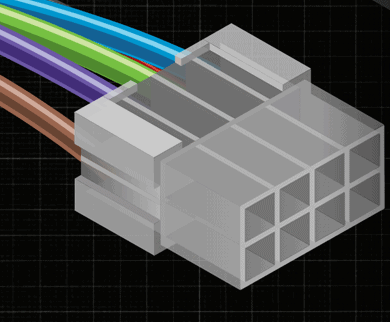

Additionally, we offer overmolded cable assemblies with connectors directly molded onto the cable for improved protection and strength. Consolidated Electronic Wire & Cable also offers a selection of standard cable assemblies, ready for purchase with pre-configured standard designs.

The Key Benefits of Well-Designed Cable Assemblies

Quality cable assemblies deliver exceptional reliability, efficiency, and safety. Properly designed and constructed cable assemblies should be able to perform three primary functions:

- Protect employees, technicians, and bystanders from electrical shock

- Create an organized system that streamlines system installation and maintenance

- Minimize the effects of wear and environmental hazards on cable function

Additional benefits of well-designed cable assemblies include:

- Improved Lifespan and Durability. Cable assemblies made with the highest-quality materials and the latest manufacturing methods are better able to resist wear and tear. This helps to extend their longevity and reduce overall maintenance costs.

- Reduced Electromagnetic interference (EMI). Cable assemblies designed with grounding and shielding properties mitigate EMI to prevent malfunctions and ensure consistent performance.

- Cost-Efficiency. Well-designed cable assemblies reduce maintenance requirements, enhance product lifespan, and streamline installation for improved cost-effectiveness.

- Enhanced Customization and Flexibility. Cable assemblies have a range of customization options and modular designs to suit a user’s application while delivering exceptional performance.

- Aesthetic Appeal. Cable assemblies with sleek and aesthetically appealing designs enhance product appearance and installation.

Understanding the Cable Assembly Manufacturing Process

- Design. In the design phase, designers and engineers work closely with customers to outline their needs and constraints. These requirements and restrictions are used to create and digitally test potential designs.

- Prototyping. In the prototyping phase, physical models of potential cable assembly designs are created. These units are used to test for functionality and manufacturability, ensuring they can be made and used as intended.

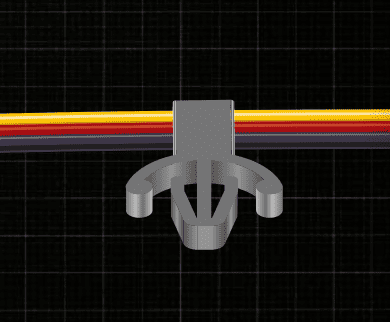

- Production and Assembly. In the production and assembly phase, the cable assemblies are manufactured as per the approved final design in the desired volumes. The manufacturing process consists of many steps, including cutting the conductors, establishing their connections, and assembling them into a single wrapped jacket.

- Testing. In the testing phase, the completed assemblies undergo rigorous testing to ensure they perform safely and effectively. The exact tests depend on industry and application requirements.

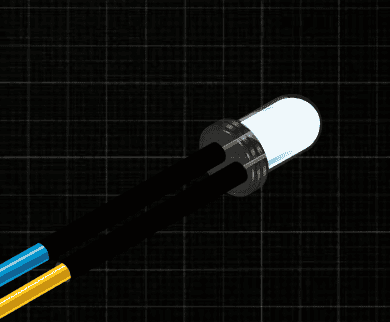

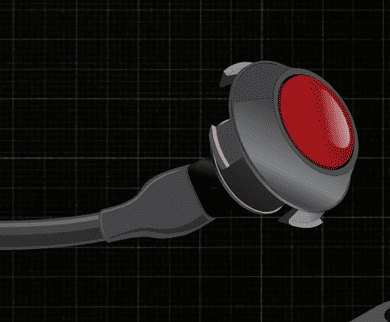

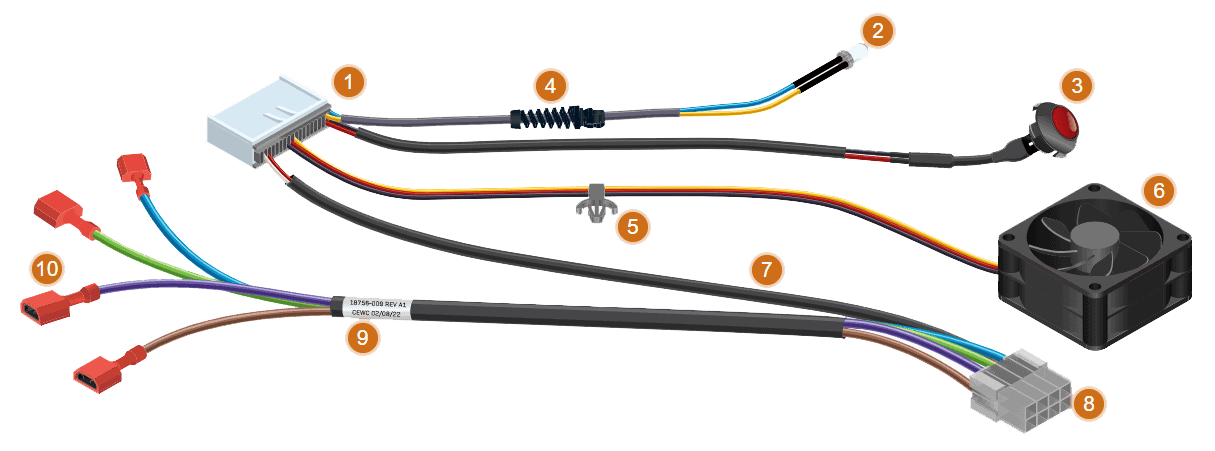

The Components of a Cable Assembly

The Components of a Cable Assembly

Common Applications of Cable Assemblies

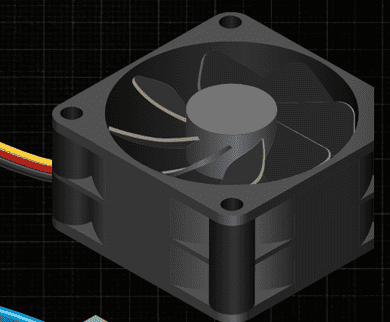

Cable assemblies find application in nearly every industry, including, but not limited to, the following:

- Medical. Medical devices, such as diagnostic, monitoring, and imaging tools, utilize cable assemblies for power transmission. Since they are used in a hospital setting, these assemblies must be disposable or able to withstand frequent and intensive sterilization procedures.

- Military. Cable assemblies used in defense equipment are often exposed to extreme environments. They must protect cables against vibrations, humidity, thermal fluctuations, and saltwater spray, among other exposures. Additionally, they must comply with stringent military specifications to ensure that they will perform reliably when it counts.

- Aerospace. Aerospace application demands are similar to military and defense demands; cables may be exposed to extreme conditions, which they must be able to endure to prevent catastrophic failure.

- Automotive. Automotive cable assemblies are highly complex and regulated. Since they are used to power critical vehicle components, such as the steering wheel and power distribution systems, they must withstand impact, vibrations, and temperature fluctuations without failing. The diversity of automobile brands and parts also means that cables must often accommodate non-standard, proprietary, or out-of-date components. Custom automotive cable assemblies are the simplest way to meet these varied challenges with minimal hassle or expense.

- Telecommunications. Telecom cable assemblies are unique in that they primarily contain fiberoptic cables meant to enable rapid, uninterrupted data transmission. For this reason, they must be shielded against interference.

- Industrial & Factory Control. Industrial facilities use cable assemblies to power equipment and relay information to control and quality assurance systems.

The Consolidated Advantage

Selecting the right cable assembly manufacturer ensures the performance and quality of your products. It is essential to work with an expert in custom cable manufacturing to ensure you receive a reliable solution that meets your unique requirements.

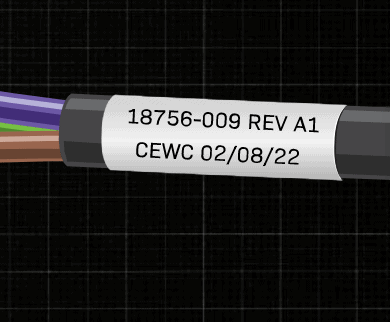

Consolidated Electronic Wire & Cable is your complete source for both standard and custom cable assembly products. As an ISO 9001:2015-certified company, we strive to manufacture top-quality products that exceed customer expectations. We also maintain various other certifications to illustrate our dedication to quality.

By partnering with us for your cable assembly needs, you can benefit from the following:

- Reduced procurement costs

- Convenient distribution center

- Unparalleled quality

- One-stop shopping experience

- Superior custom capabilities

With more than 100 years of experience, we can successfully deliver cable assembly solutions that adhere to the most demanding industry standards. We continuously improve our manufacturing processes and conduct rigorous quality assurance processes to ensure we deliver the best possible products that perform as needed.

Client Success Stories: Our Project Portfolio

Additional Resources

Get the Perfect Cable Assembly for Your Needs: Contact Our Experts Today!

Consolidated Electronic Wire & Cable is a custom cable assembly manufacturer offering seamless industrial cable assembly solutions. Our well-designed cable assemblies deliver various benefits, including cost-effectiveness, longevity, and a range of customization options to suit your specific needs. For more information about our cable assembly capabilities, or to get started on your custom solution, contact us or request a quote today.

() Quote Cart

() Quote Cart