What Are the Benefits of Custom Cable Assemblies?

Compared to standard cable assemblies, custom cable assemblies benefit users in many ways, including:

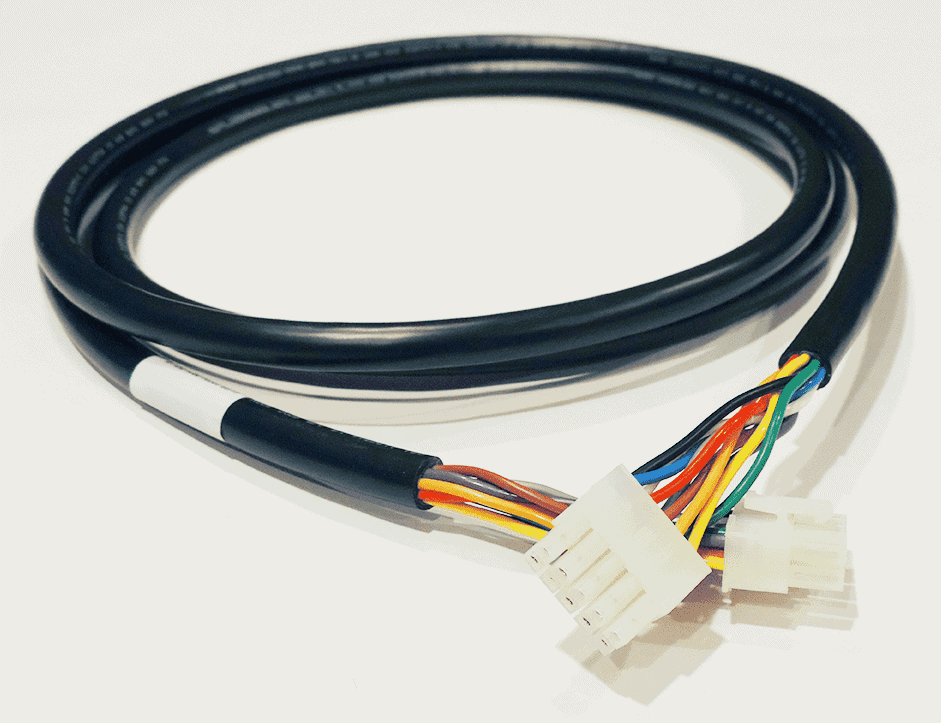

- Accuracy: Custom cable assemblies are manufactured to the client’s exact specifications. As a result, they fit the application better than standard cable assembly units.

- Materials: The materials used for shield, insulation, and jacketing determine how a cable assembly performs in a given environment. Custom cable assembly allows users to choose the materials that best suit their unique needs.

- Flexibility: Nearly every feature of a custom cable assembly can be tailored to the application, so clients can choose elements that streamline its use.

- Performance: In a custom cable assembly, every design decision is made with a specific application in mind, so the final product will operate and perform as intended.

- Quality control: Testing is an integral part of the custom cable assembly process. The final product undergoes rigorous testing to ensure compliance with application- and industry-specific requirements, so you can be confident that your assembly will hold up within your application.

- Cost and time savings: Cable assemblies are not one-size-fits-all, but it can be costly and time-consuming to force a standard assembly to suit your needs. Clients who attempt to do so often waste time modifying cable lengths and connector ends. These expenses can be eliminated by choosing custom solutions from the beginning.

Consolidated Custom Cable Assembly Capabilities

At Consolidated, here's how we set ourselves apart from other cable assembly manufacturers:

Customization options: Whether you require residential, commercial, or industrial cable assemblies, we have the resources to customize your cable solution and meet your application's exact requirements.

Turnkey solutions: At Consolidated, it's our goal to be a one-stop shop. We provide end-to-end solutions ranging from assembly design to final testing.

High-performance designs: Backed by over a century of experience in the industry, Consolidated delivers reliable, quality designs that comply with your unique specifications.

Quality engineering: Through careful engineering, the Consolidated team produces cable assemblies that are easy for you to install, maintain, and replace, as needed.

Turn time and cost reductions: We prioritize efficiency in our processes. In this way, we're able to offer you fast turnaround times and reduced costs.

Bulk purchasing: Regardless of the complexity or type of project, Consolidated can offer you bulk purchasing options.

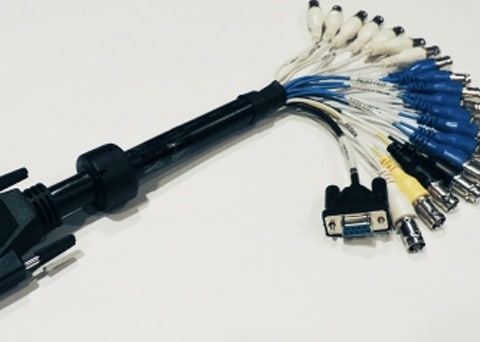

Our Cable Manufacturing & Assembly Solutions

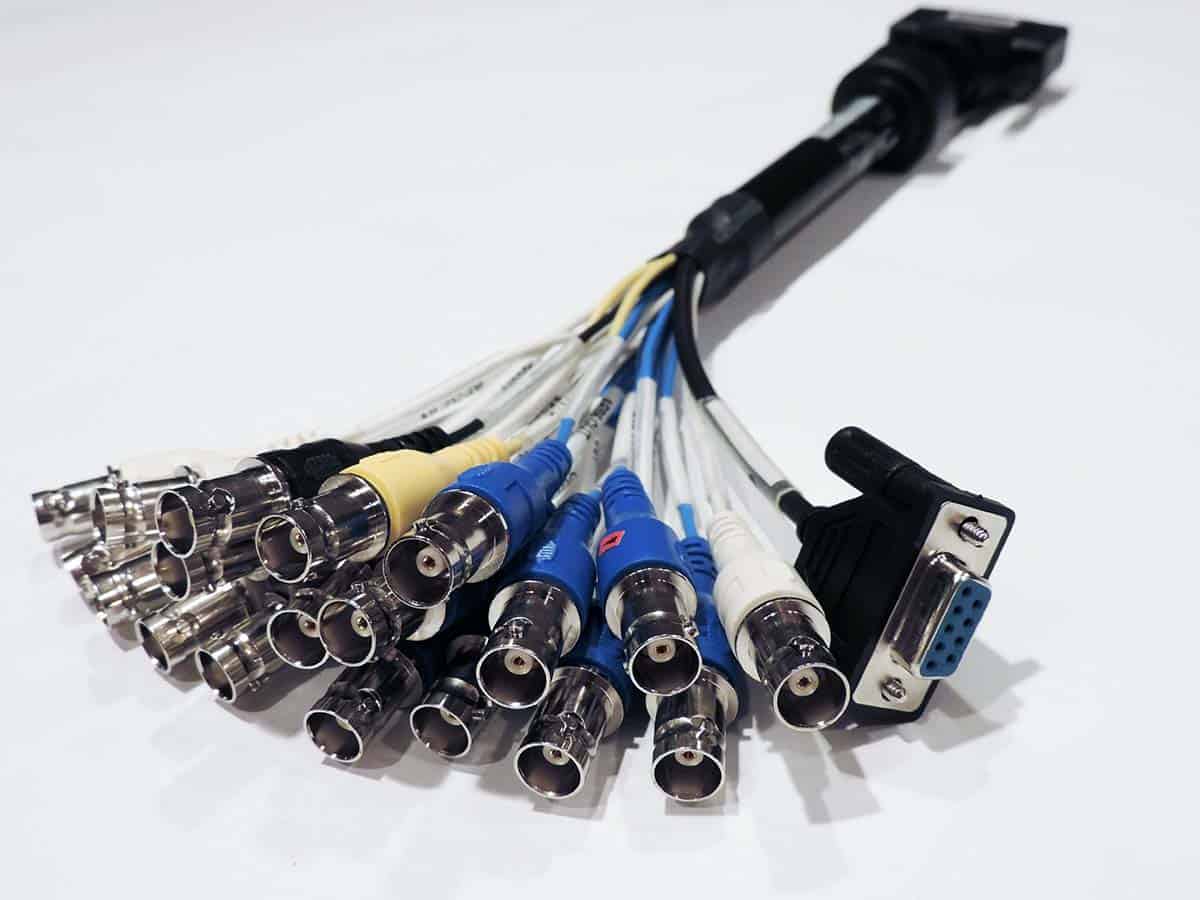

- Molding and overmolding

- Wire crimping and braiding

- Ultrasonic welding

- Cut and shrink tubing

- Tinning and soldering

- In-line engineering

Testing & Quality Assurance

The Consolidated team will tailor our comprehensive testing processes to address the requirements of your specific project and industry. We also monitor quality during design and production, employing a stringent quality assurance process to help ensure that your custom cable assembly is of the highest quality and will function reliably in your application.

Our Certifications

Our wide range of certifications stands as a testament to our quality and reputation. Those certifications include:

Why Work With Consolidated Electronic Wire & Cable?

Consolidate has been delivering reliable solutions for over 100 years. We are a one-stop shop for custom and standard electronic wire, cables, wire harnesses, molded cable assemblies, and power supply cords.

Client Success Stories: Our Project Portfolio

Additional Resources

Contact Consolidated for Unmatched Expertise & Quality Custom Cable Assemblies

Choosing custom cable assemblies rather than an off-the-shelf option allows you to optimize your assembly’s design and performance for your exact requirements, all while reducing turnaround times and expenses. Whether you need a cable assembly for medical diagnostic devices, factory automation systems, or anything in between, the expert team at Consolidated is here to help.

As a custom cable assembly manufacturer since 1919, Consolidated aims to be your single-source manufacturing partner for all your electronic cable and wire needs. Our extensive product line covers everything from custom cables and molded cable assemblies to wires and wiring harnesses. We’ll help you select the ideal cable and wire solution to meet your unique specifications and fulfill the needs of your application.

Contact us to learn more about our capabilities for custom cable assemblies, or request a quote today to get started.

Have Questions? – Fill Out the Form Below to Get Started

"*" indicates required fields