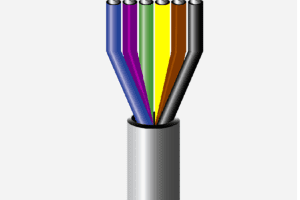

Consolidated’s line of multi-conductor wire is designed for use in a number of communications applications, such as public address systems, remote control circuits, actuator controls, audio and sound systems, and data transmission.

Insulations are available in various UL styles, and color coded PVC, or with a chrome gray PVC outer jacket with temperature ranges from (CM) -20°C to 80°C (-4°F to 176°F) and (UL) -40°C to +80°C depending on the application. Multi-conductor cable is available in configurations from 2 to 60 conductors, in various jacket thicknesses depending on the conductor count.

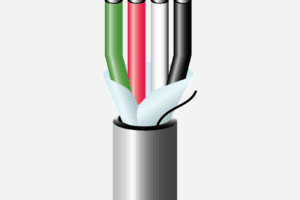

Consolidated Electronic Wire & Cable also offers 14 to 24 AWG foil shielded cable available in 2, 3 and 4 conductor configurations.

This cable is constructed with annealed stranded tinned copper wire, polyethylene color coded insulation and Polyester aluminum foil shields with a stranded tinned copper drain wire.

In addition, a 20 AWG, 22 AWG, and 24 AWG, we have cable that is available with up to 60 conductors, and features semi-rigid PVC insulation, 85% coverage tinned copper wire braid shielding and a gray PVC jacket.

Check out our best products: Electronic Cable | Power Supply & Retractile | RG & Coaxial Cables | Custom Made Cable | 16 AWG Wires | UL Style Cable & Wire | Coax Broadcast Cable | SJTW Cables | Technical Information | Top Power Supply | Flexible Wire | Tin Wire | UL Style 1007 and UL Style 1569

Top blog posts: American Wire Gauge | Molded Cable | Rohs | What Are NEMA Standards? | BestPower Cord Jackets

The Versatility of Multi-Conductors

From the instrument panels controlling heavy equipment to the most delicate professional sound systems, modern assemblies rely on conductors for power, operations, and much more.

Different applications demand different levels of resistance and conductance, meaning that wires of all different materials, gauges, and combinations are available, fine-tuned for specific purposes. The multi-conductor cable is an ideal example of a stranded, highly versatile style of wire, particularly popular in the communications industry.

What is a Multi-Conductor Cable?

Multi-conductor cables are a unique variation of stranded wire, with each cable hosting at least two (and often many more) distinct conductors inside of a common jacket. Depending on the configuration, these cables can offer up to 60 distinct conductors, all bundled in one stranded wire product, with both solid and stranded conductors wound together.

One of most diverse types of cable available in today’s marketplace, the variations of conductor quantity (and quality) offered in a single multi-conductor cable make it an ideal fit for applications requiring complex transmission of power, communications signals, controls, and access information.

Its three most popular variations include:

Non-plenum or riser cable is run between floors and in non-plenum building areas. Both plenum and non-plenum cables typically require high-tensile strength, as they may run or dangled through open chutes on a regular basis.

Because they are frequently used in vertical and load-bearing applications, these cables often incorporate additional strengtheners or physically stronger conductor choices.

Plenum cables are specially rated to run through a building’s plenum spaces and HVAC system areas. Requiring unique jackets and insulation to withstand extreme temperatures and rigorous fire safety codes and standards, they often feature low-smoke PVC or FEP materials.

Telephone and network communication cables require plenum-rating as they typically run throughout buildings, offering an easy route for the spread of fire.

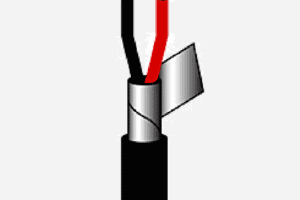

Shielded cable incorporates a common conductive layer beneath its jacket, which offers the cable a Faraday cage. This electromagnetic shield minimizes noise and interferences to maintain clarity of signals and also reduces electromagnetic radiation.

Common Conductor Materials

Conductors can be crafted from electrolytes, metals, plasmas, graphite, and even conductive polymers, as well as superconductors and semiconductors.

Common metals include:

- Copper, often recognized for its high conductivity

- Annealed copper, the international electrical conductor standard

- Silver, highly conductive but the least practical material due to cost

- Aluminum, a low-cost conductor ideal for low-voltage distribution and high-voltage transmission

- Steel, clad with either aluminum or copper for an appropriate level of conductivity

Common Jacket and Insulating Materials

To meet specific needs, specialty cables can also be customized in other ways. The actual conductive metals that make up a cable are enhanced by the insulating material, or jacket, wrapped around them. The weight, flexibility, and protective qualities of this additional layer can have a major impact on the cable’s final performance in a given application.

Jacket materials are responsible for reducing current leakage as well as protecting the cable assembly from its surrounding environment. Common choices for insulators include:

- Neoprene, an oil-, flame-, and chemical-resistant synthetic rubber

- EPDM (ethylene propylene diene monomer) elastomer, a highly flexible compound that performs well over a wide temperature range

- Silicon rubber, which offers superior flexibility

- Mica tape, an insulator with extremely high temperature resistance

- Thermoplastic (PT, PVC, Teflon™, Tefzel®, etc.), a family of materials with excellent insulation, high flexibility, and resistance to moisture and chemicals

Depending upon the conductor count and configuration of a cable, jacket thicknesses and temperature resistances vary, ranging from (CM) -20 degrees C to 80 degrees C and (UL) -40 degrees C to over 80 degrees C.

In addition to insulation, a shielded cable may be wrapped with metal braiding, metal tape, or foil braiding. This additional layer of material provides electromagnetic shielding for the cable, preventing any additional electrical noise from interrupting signal transmission. It also reduces the cable’s electromagnetic radiation emissions. These shielded cables often feature a drain wire — usually made of copper or tinned copper — to provide additional grounding.

Sizing and Gauge in Multi-Conductor Cables

Widely available between 14 and 24 AWG (American Wire Gauge), the size of these cables can be deceptive depending upon the various jacket thicknesses needed for a project. Typically, gauging is named based upon the number of dies a standard wire size passes through during production. With every six-gauge increase, a wire’s diameter doubles, and with every three-gauge increase, a wire’s area roughly doubles.

However, air pockets and insulation varieties in cables and stranded wire make sizing slightly trickier — especially when evaluated by the naked eye. These cables take up significantly more physical space than a single, solid conductor, as the gauge is measured based specifically upon the sums of each individual conductor’s cross-sectional area, not its overall size.

Some of the more common everyday gauges for multi-conductor cables and their applications include:

- Speaker Cable, 14-16 AWG

- Coaxial Cable, 18-20 AWG

- Cat 5, Cat 5e and Cat 6 (LAN and Ethernet), 24 AWG

- Telephone Cable, 22-28 AWG

Industries and Applications

The versatility, ruggedness, and countless customization choices make these cables a key tool in a wide range of industries, and in thousands of everyday applications.

This unique material can be found in:

- Medicine and medical electronics

- Computers and digital peripherals

- Communications technology

- Audio and sound systems

- On-machine controls

- Instrumentation and control panels and equipment

- Wire harnesses and cable assemblies

- Data transmission tools

- Public address and integrated speaker systems

- Security, surveillance, and alarm systems

- Remote control circuits

- Actuator controls

- Low-voltage power supplies

- And more

Learn More

For nearly 100 years, Consolidated Electronic Wire & Cable has delivered custom cable solutions to various industries for a wide range of applications, including multi-conductor cable arrangements for communications professionals. To learn more about the best cable solution for your next project, reach out to us today.

[/expand]

() Quote Cart

() Quote Cart