Wire and cable applications and installations rely upon many different technical terms that may not be familiar to those outside the industry. This blog will define many of these terms to help readers develop a thorough understanding of terminology used in the wire and cable industry.

A

Abrasion – The wear that occurs when a material is frequently exposed to a coarse surface. In the cable and wire industry, abrasion refers to the cable’s protective jacketing being worn away by rough surfaces and environmental conditions.

Abrasion resistance – When some materials have inherent resistances to abrasive forces, making them ideal for applications featuring exposure to abrasive wear.

Alternating current (AC) – When the direction of an electrical current is reversed at standard intervals, this is known as alternating current. The rate of these reversals is measured in Hertz (Hz).

Accelerated life test – A series of comprehensive tests that simulate the harsh operating conditions of various wires and cables. Common tests in this category include the torque test, the elephant test, and the shake and bake test.

Ambient temperature – The temperature of liquids and/or air and gases surrounding a wire or cable.

AES/ABU – A common audio standard jointly established by the Audio Engineering Society and the European Broadcast Union.

American wire gauge (AWG) – One of the most common forms of measurement for wire diameter. A smaller AWG means a larger wire gauge.

Ampacity – The current limit of a conductive material before it becomes too hot to operate safely.

Amperes (amps) – The standard unit for measuring electrical current flow. One ampere equals one coulomb moving past any given point in the conductor in one second.

Annealed wire – The annealing process heats and then slowly cools wire to give it additional toughness and reduce internal stresses in the material.

Attenuation – Signal or power loss that occurs as an electrical signal travels along a wire/cable. Typically measured in decibels (dB) per unit length: i.e. dB/foot or dB/km. In optical fiber cables, attenuation is the ratio of input power vs. output power, measured in decibels per unit length.

B

Balanced line – A cable containing two matching conductors, but each conductor carries voltages featuring equal magnitudes and opposite polarities.

Bare conductor – A conductor without any jacket or insulation.

Bare copper bus bar – Bus bars (or buss bars) facilitate easier distribution of electrical currents. These bare metal strips are typically made from aluminum, brass, copper, or other metals that conduct electricity while acting as a grounding material.

Bare copper (BC) — Stranded – A wire wound from bundled bare copper wires.

Bare copper-clad aluminum (BCCAL) – Wire with a bare copper coating and an aluminum core.

Bare copper-clad steel (BCCS) – Wire with an aluminum coating and a steel core.

Bending radius – The minimum radius a cable or wire can be bent without damaging it.

- Single or multi-conductor cable without metallic shielding = 8 times the overall cable diameter (Multi Cable)

- Single or multi-conductor cables with tape shielding = 12 times the overall cable diameter

- Multi-conductor cables with individually shielded conductors = 12 times the individual cable diameter (pairs, triads, etc.) or 7 times the overall cable diameter. — whichever is greater

Booster – An amplifier added to a cable or wire to reduce signal loss.

Boot – An additional protective wire/cable covering beyond standard jackets or insulation.

Bits per second (BPS) – BPS is a common measurement of speed for data transference in wires and cables.

Braid – A tube-shaped woven covering used to impart additional strength or protection to a wiring. Braiding may be made of many materials, such as copper and copper fibers, glass, and nylon, among others.

Breakdown voltage – The voltage level necessary to destroy the insulation between two conductors.

Buss bar – An uninsulated wire made from tinned copper, typically used as a standard lead wire.

C

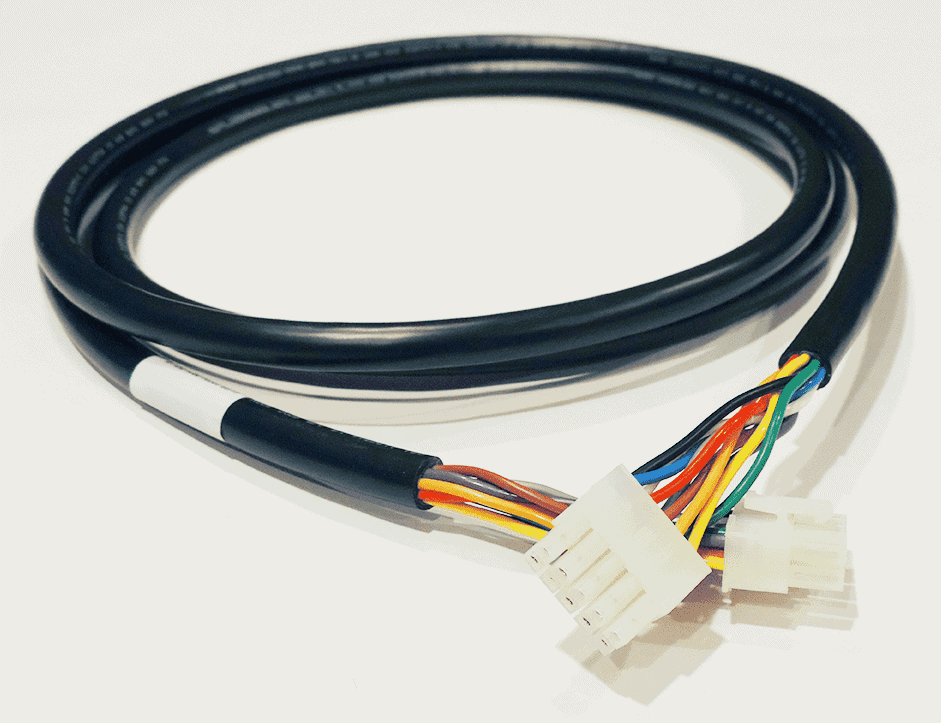

Cable – Helically twisted group of insulated conductors.

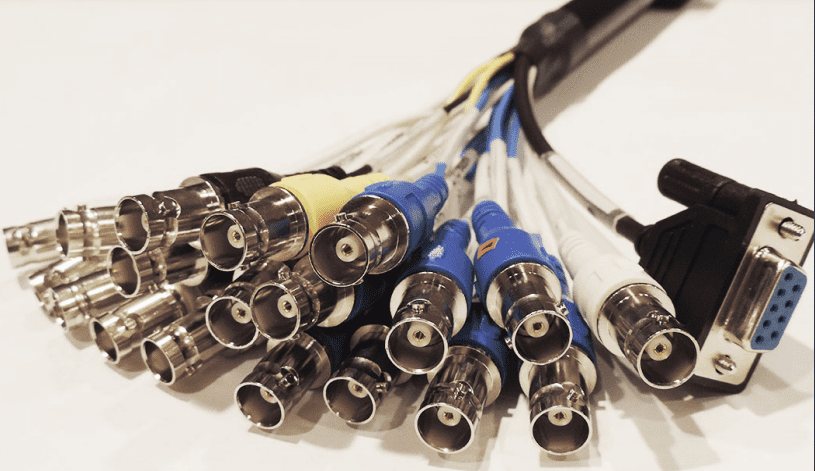

Cable assembly – A length of cable with connectors on one end or both ends.

Capacitance – The ability of two conductors to store electrical energy when separated by an insulator.

Center conductor – The innermost central conductor found in a coaxial cable.

Coated wire – Wire coated thinly with metal using a dip bath application method.

Coaxial cable – A cable consisting of conductors and insulating layers along the same axis. This construction contains signals within the cable with minimal interference from external factors.

Color code – A color-based coding system used to identify various wires, cables, and related components. Federal, state, and local municipalities may each have requirements for codifying wires and cables. In some jurisdictions all wire colors are specified in legal documents. In other jurisdictions, only a few conductor colors are so codified. In that case, local custom dictates the “optional” wire colors. View All About Circuit’s infographic here.

Composite cable – Cables with conductors of different AWG sizes or consisting of more than one type of cable.

Conductivity – The capability of material to carry an electrical current.

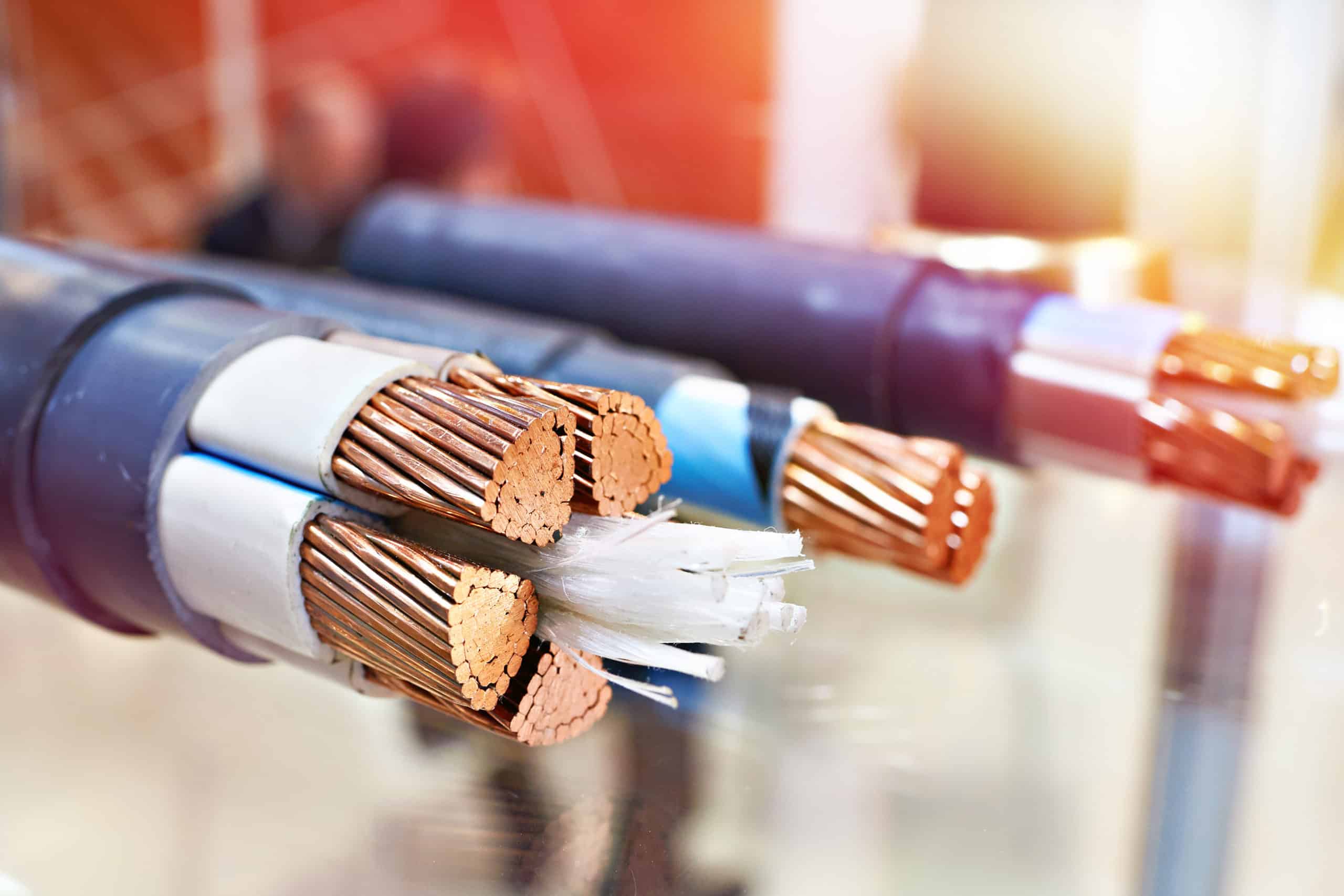

Conductor – A material that transmits electrical current.

Conduit – Metal or plastic tubing which cable or wire can be run through.

Connectors – Devices that facilitate the flow of electricity between cables or between a device and a cable.

Coupling – Energy transfer between two cables in a circuit when there is no direct electrical contact.

Cycle life – Refers to the amount of flexes a wire/cable will withstand before it breaks down.

D

Direct current (DC) – Electrical current that travels in only a single direction. One real-life illustrative example of direct current is a battery. Batteries have positive (+) and negative (-) terminals. If you connect the positive and negative terminals on a battery with a wire, the electrons in the wires will begin to flow to produce a current.

Decibel (dB) – This unit of measurement refers to a difference in power levels and may be used to measure sound, pressure, or voltage, among other factors.

Dielectric – An insulating material used between conductors that facilitates electrostatic repulsion and attraction.

Dielectric breakdown – When the voltage limits of a dielectric are exceeded, the dielectric will then experience breakdown and become conductive.

Dielectric loss – When friction from alternating electric fields results in power loss.

Dielectric strength – The voltage limit of a dielectric before it experiences dielectric breakdown. Expressed in terms of Volts per unit thickness. The higher the dielectric strength of a material, the better an electrical insulator it is.

E

Extruded cable – Extruded wire is fabricated in a continuous extrusion process while the insulation material is applied simultaneously.

F

Feedback – When electrical energy from a higher point in the circuit is applied to a lower point in the circuit.

Ferrous – A material containing iron.

Flame resistance – Refers to a material’s ability to resist fire propagation when removed from the heat source. Also refers to a wire or cable’s ability to operate while on fire. Flame resistant cables and wires are common in critical circuits for life support, fire suppression, and other safety applications.

Flat cable – A cable with two or more conductors on a parallel plane and covered by an insulator. Also known as planar cables or ribbon cables.

Flat conductor – A conductor with a width-to-thickness ration of 5:1 or more.

Flex life – The amount of times a cable will bend before it breaks. Naturally, products in need of flex life are those that will be used in a rigorous environment in which the cable will be repeatedly bent, twisted, etc. Different design considerations must be taken into account depending on the flex the cable must endure in application.

Flexibility – The capability of a cable to bend in varying radii.

G

Gauge – A wire’s diameter.

Gain – An increase of current, voltage, or other power readings compared to a standard reading.

Ground – The electrical connection between a circuit and the earth or some other large connecting body.

Ground conductor – A conductor in a cable or line that is grounded to the earth or some other large connecting body.

H

Harness – A wire or cable assembly, wherein wires and/or cables have been tied together or pulled into a plastic sheath for easier organization or protection. A wire harness is a common and effective tool for keeping multiple wires within a piece of equipment in order. On a more basic level, it’s the exterior covering, or sleeve, that encases and protects an inner conductor or bundle of conductors.

Helical stripe – A spiral stripe put on a conductor to facilitate circuit identification.

High-tension cables – High-voltage wires, typically used to facilitate ignition in combustion engines.

Hook-up wire – A lone insulated conductor wire used internally in most common electrical equipment, such as appliances and computers. Designed for reliable performance, these wires are built to comply with strict industry standards and quality assurance needs. Hook-up wire frequently finds application in enclosed electronic equipment including control panels, meters, computers, and automotives.

I

Impedance – The amount of opposition a circuit offers to the flow of AC current at a given frequency.

Inductance – A wire’s ability to store electrical current in the magnetic field surrounding the wire.

Induction – The creation of a magnetic field or voltage caused by other surrounding magnetic fields or voltages.

Insulation – A material with favorable dielectric processes used to separate various conductors in a wire or cable.

Interference – Electromagnetic or electrical disturbances that produce unfavorable responses in other electrical equipment. The four most common types of interference include:

- Crosstalk. Super imposition of pulsed DC or standard AC signals between nearby cables.

- Common mode noise. Interference caused by currents flowing between different grounds within a system.

- Magnetic noise. Magnetic fields in large motors, transformers, or other equipment cause current to flow in opposition to the equipment.

- Static noise. When a nearby electrical field distorts a signal.

International Standards Organization (ISO). An independent body that implements standards, guidelines, and regulations for a broad range of industrial and commercial equipment.

J

Jacket – The protective covering of a wire or cable. May or may not be insulating.

Joint – An area of wire or cable where groups of wires may be joined using a variety of methods, such as soldering, welding, brazing, or by mechanical means.

Jumper – A short piece of wire or cable used to circumvent a break in a circuit or a space between circuit boards.

L

Laminated cable – A cable that uses two sheets of laminate material to guarantee a predetermined pitch. May be insulated or uninsulated.

Lay – The length of one full turn around the axis of a cable or conductor.

Lay direction – The direction of a cable’s spiral twist along its axis when looking away from the observer.

Lead dress – The way wires and other components are placed or routed in an electrical circuit.

Leakage – Unintentional passage of electrical current over or through the insulator. In a cable television application, leakage is a two-way phenomenon; when signals can get out, over-the-air signals can also get in.

Low frequency (LF) – Low frequency waves typically refer to radio waves in the 30 – 300 kHz range. Special wire formations, such as Litz wire, are required to mitigate interference in this frequency range.

Line drop – A voltage loss that occurs between two points in a power or transmission line.

Low loss dielectric – An insulator that features low dielectric loss, such as those used in wireless communication systems.

M

Margin – The space between the reference edge of a cable and the nearest edge of the first conductor.

Mil-Spec – Short for Military Specifications. A Department of Defense standard for all equipment and technology manufactured for use by the military. Many other high-performance industries default to Mil-Spec wires and cables to guarantee performance in harsh environments. Mil-Spec wire can be used in a multitude of applications, including but not limited to: safeguarding and protective housing, airframe cable, point-to-point wiring, antennas, bus-bar, ground wire, and bonding moving parts.

Molded cable – Cables with connectors that are directly plastic-molded onto the cables to facilitate a mechanical connection between the two. Molded cables are designed to fit a number of different types of connectors and serve various purposes, including protecting cables from the elements.

Multi-conductor cable – A cable with multiple conductors.

Multi-pair individually shielded cable – Wires wrapped in aluminum foil to provide shielding from external interference. These cables are typical in applications requiring absolute signal isolation.

N

National Electrical Manufacturers Association (NEMA) – NEMA provides performance, manufacturing, and design standards for a broad variety of industrial components and equipment. For example, NEMA rates wires and cables for corrosion resistance, contaminants, and resistance to environmental factors such as ice, snow, and rain.

Nickel chromium resistance wire 60% – A formulation of 60% nickel and 16% chromium is the industry standard for metallic resistance wires used in heating devices and similar applications.

Non-contaminating vinyl – PVC and other similar vinyl materials are often chosen for sleeves or coatings because they omit plasticizers that can seep into the surrounding environment of cables and wires.

Non-paired cable – A cable with multiple conductors that aren’t set up in a paired configuration.

O

Ohm – A unit for measuring electrical resistance.

Output – Usable signal or power delivered from a device or circuit.

P

Paired cable – Cables wherein the conductors are paired in groups of two to facilitate a more balanced signal transmission. Due to the improved noise immunity of twisted pairs, they generally permit higher data speeds than multi-conductor cables.

Periodicity – Impedance variations in the cable are evenly spaced, causing additional signal reflections.

Pitch – The distance between the centers of two conductors within the same cable.

Planar cable – A cable with two or more conductors on a parallel plane and covered by an insulator. Also known as flat cables or ribbon cables.

Plating – Allowing current flow by evenly coating a surface with conductive metal. Copper is the most commonly used metal for plating, though others are also used. Plating offers a more cost effective solution to using precious metals.

Plenum cable – A cable approved by the Underwriters Laboratories (UL) for use in plenum spaces without a conduit. For example, plenum cables are beneficial in a space used for air circulation in heating and air conditioning systems, usually between the structural ceiling and the suspended ceiling.

Point-to-point wiring – Wiring that terminates at a circuit at each end.

Polyethylene – Can be used as a buffer to prevent harm to electronics caused by corrosion or vibration.

Portable cord – A cable with multiple twisted conductors for use in a variety of applications. Also known as a flexible cord.

Power loss – The difference between the total power delivered to the cable and the output of power into the subsequent device.

Primary insulation – The first insulative layer over the conductor, primarily acts as an electrical barrier.

Product AWG – Classification of wire or conductor diameters using American Wire Gauge standards.

Product characteristic impedance – The total resistance of a conductor. Measured in Ohms.

Product direct material – A full accounting of all physical materials used to fabricate a product, including spoilage and scrap.

Pulling eye – An eye which attaches to cable or assembly. A hook is attached to the eye to pull the cable through a duct or tube.

Polyvinyl chloride (PVC) Type 1 – A thermoplastic insulator commonly used in cabling and other industrial applications.

PVC (FR) – Fire-resistant PVC.

Q

Quad – A cable with four conductors.

R

Rated temperature – The maximum operating temperature an electrical component can endure for long periods without damage or breakdown.

Rated voltage – The maximum operating voltage an electrical component can endure for long periods without damage, breakdown, or safety hazard.

Recovered diameter – The post-shrinking diameter of heat-shrink tubing.

Reference edge – The edge of a cable from which measurements are made.

Resistance – A measurement encompassing the complexity of passing an electrical current through a medium when voltage is applied.

Retractile cord – A cord featuring a special jacket or sleeve that retracts like a spring to return the cable to its original form after it is extended or compressed. These cords are made of either polypropylene (PP), polyvinyl chloride (PVC), or thermoplastic elastomer (TPE) to insulate the copper wire inside. Two common examples of retractiles cords are USB chargers and life support machines.

Radio Guide/Universal (RG/U) – A military designation for coaxial cable.

RHH – A heat-resistant, rubber-insulated building wire.

RHW – A rubber-insulated building wire featuring moisture and heat resistance.

Ribbon cable – A cable with two or more conductors on a parallel plane and covered by an insulator. Also known as flat cables or planar cables. Ribbon cables are commonly used when only limited space is available since they lay flat and take up little room.

Rope strand – A conductor made from groups of twisted strands.

Round conductor flat cable – A cable made from parallel round conductors on the same plane.

Routing – The path a conductor or cable follows.

Rubber wire insulation – Wire insulations made of thermoset elastomers.

S

Semiconductor – A material with electrically conductive properties between that of an insulator and a conductor. Semiconductors are key elements in the manufacture of electronic systems, serving communications, signal processing, computing, and control applications.

SEOOW – Short for service, thermoplastic elastomer, oil-resistant insulation, oil-resistant jacket, water and weather resistance.

Separator – An extra layer of insulator. Usually between the jacket and wiring, the conductor and dielectric, or between components in multi-conductor cables. Common examples are textile, paper, mylar, etc. within various electrical wire and cable applications.

SEW – Silicone rubber-insulated equipment wire.

Sheath – The outermost protective coating which may or may not provide additional insulation to a cable. Also called a jacket.

Shield – Braiding, tape, or other covering used on electric cables and components to reduce or prevent signal interference and/or leakage.

Shield coverage – The physical space covered by shielding material.

Shield effectiveness – The efficacy of a shield material in blocking signal interference and leakage. The electrical environment, the cost of the cable, the cable’s diameter, weight, and flexibility are all factors that impact the amount of shielding required.

Signal cable – A cable specifically engineer to carry less than a single ampere per conductor.

SJEOOW – Flexible cables commonly used in harsh industrial indoor or outdoor environments. The acronym stands for service or hard service cord, junior service cord rated at 300 volts, thermoplastic elastomer, oil-resistant insulation with an oil-resistant outside jacket, and weather/water resistance.

Sleeving – A protective tube made by weaving, braiding, or extruding. Sleeving is most often used as a cable management solution for containing cables.

Solid conductor – A conductor made from a single wire with reduced flexibility but increased strength.

Span – Distance between the centers of the first and last conductors in a flat cable.

Spiral wrap – A helically wrapped material around a core.

Strand – An individual, uninsulated wire. Referred to in the same way as an individual piece of hair.

Stranded conductor – A conductor formed from multiple strands or from groups of uninsulated wires.

Strip – The process of removing insulation from a wire.

Surge – A substantial but temporary voltage increase within a wire or cable. For example, the standard voltage rating on a United States landline is 120 volts. If this is exceeded, it would be considered a surge.

T

Tape wrap – A spiral wrap of tape on a wire.

Temperature rating – The ideal operating temperature range (minimum and maximum) of an insulating material before it experiences damage or breakdown. Important temperature ratings in the wire and cable industry include:

- Maximum operating temperature: maximum continuous temperature that the wire can withstand during its lifetime

- Minimum cold bend temperature: the lowest temperature at which a wire can be bent without cracking

- Minimum installation temperature: the lowest installation temperature for a given wire or cable

- Minimum continuous flexing temperature: the lowest temperature at which a wire can withstand repeated flexing throughout its lifetime without damage

Thermocouple extension cable – A cable made from single or multiple twisted thermocouple extension wires within a common protective sheath.

Thermocouple extension wire – Paired wires made from different alloys with complementary EMF-temperature properties.

Thermoplastic – A polymer material that is soft when heated and firm when cooled. Common examples of thermoplastics include acrylic, polyester, polypropylene, polystyrene, nylon and Teflon.

Thermoset – A polymer which hardens permanently when heated and set. Common examples of thermoset plastics and polymers include epoxy, silicone, polyurethane and phenolic.

THHN – Nylon-jacketed building wire commonly used in wet or dry applications for construction, industrial equipment, control circuits, and more.

Tin copper braid – Tin coatings or braided sleeves are sometimes added to copper conductors to mitigate corrosion or improve soldering capabilities.

Tolerance – The acceptable level of variation from design specifications without impeding functionality.

Thermoplastic elastomer (TPE) – A flexible compound made from rubber and plastic, often used as an insulator in wires and cables. Since TPE can be used in harsh environments, it is commonly used in portable control cables and automotive, robotics, and medical applications.

Tray – A non-combustible apparatus or apparatuses that provide structural support for cables.

Tray cable – A cable with multiple conductors or multiple pairs made to National Electrical Code standards for installation in trays. Tray cables can be rated for outdoor and indoor use, corrosive areas, hazardous locations, or high electrical noise areas.

Triaxial cable – A cable with three coinciding axes, such as a conductor, shield, and additional shield all separated by an insulator.

Triple – A cable made from three individual insulated conductors that are twisted together.

Tubing – A tube made from extruded plastic or metal.

Twisted pair – A cable made by twisting two insulated conductors together. This style helps minimize electronic interference by providing balanced signal transmission.

U

Underwriters Laboratories (UL) – A non-profit that offers a listing service for electronic and electrical materials and equipment.

Unshielded style – Lightweight, thin cable with unshielded conductors.

Unshielded twisted pair (UTP) – A very common unshielded cable used in telecommunications with an internal twisted pair that provides a balanced signal and mitigates crosstalk interface.

V

Volt – A unit of measurement for electromotive force.

Voltage – A measurement of electromotive force between two points.

Voltage drop – The voltage capable of being generated across a conductor in spite of impedance or resistance. Voltage is similar to the water pressure supplied to a garden hose. The current would be the water flowing through the hose. And the inherent resistance of the hose is determined by the type and size of the hose – just as the type and size of an electrical wire determines its resistance.

Voltage rating – The highest level of voltage a wire can continuously tolerate. Every wire/cable has a particular voltage rating property based on insulation and other materials.

W

Wall thickness – The thickness measurement of insulation or a jacket. Applications in more extreme environments require greater wall thicknesses to protect the wires inside. Unbalanced or uneven wall thicknesses can increase the likelihood of mechanical or electrical failure.

Welding – Joining the ends of multiple wires or groups of wires.

Wire – A narrow filament of drawn metal.

Contact Consolidated Electronic Wire & Cable

We hope these definitions have helped readers to increase their understanding of common terminology used in the cable and wire sector. For more information about cables and wires for your project, please contact the experts at Consolidated Electronic Wire & Cable.

() Quote Cart

() Quote Cart

Comments are closed