Consolidated Electronic Wire & Cable collaborated with a customer’s engineering team to design and develop a product that fulfilled their requirements for a high-definition audio/video pullout cable assembly.

Featuring HD-XLR, RCA and custom-molded DB connectors Consolidated designed a stronger, better designed, and less expensive assembly than our competitor.

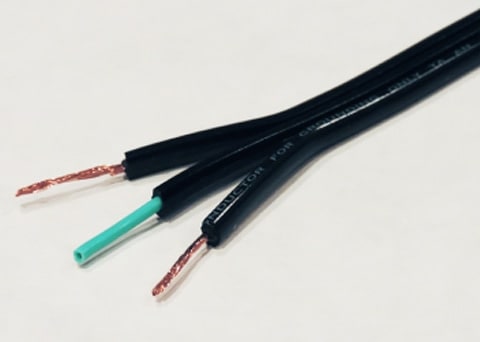

To meet the client’s performance requirements, Consolidated Electronic Wire & Cable engineered strength mechanisms into the complex cable assembly so that it could be pulled by the cord without losing a connector. Given the demands that would be placed on the product, we used an extra durable, high-quality jacket insulation suitable for high-end telecommunications.

The customized cable wire assembly, which has an outside diameter of .333”, has 7 unshielded coaxial conductors and 19 shielded coaxial conductors. It meets tolerances of +/-10%, withstands temperatures of -40oC to 80oC and has a 300-volt rating.

We performed cable performance and conductivity tests and worked within an 8 week lead time to deliver 2,000 units a month to our customer.

To learn more about this project, or for more information on our other products and services, please contact Consolidated Electronic Wire and Cable.

() Quote Cart

() Quote Cart