Coaxial cables are cylindrical cables composed of an inner metal conductor surrounded by a tubular insulating dielectric material, which in turn is surrounded by a protective tubular conducting shield and covered by an overall jacket. The term “coaxial” refers to the shared geometric axis of the tubular inner conductor and outer conducting shield. In contrast, a simple shielded cable is comprised of braided or spiral-wound strands within an insulating jacket.

What Are The Different Types of Coaxial Cables?

Coaxial cables differ in design depending on their end use. Shorter cables often appear in household applications such as AV systems or personal Ethernet connections, while longer cables can connect entire radio and television networks or long-distance phones. Micro/mini cables are also frequently used in various consumer, military, aerospace, and medical devices.

Below are some of the most common coaxial cable types and the applications they support.

Hardline

Radiating

Also called “leaky cables,” radiating cables have a similar structure to hardline but with the addition of slots cut into the shield, tuned to specific wavelengths or radio frequencies. By allowing a pre-determined amount of “leakage” between the transmitter and the receiver, these cables can be implemented in locations where antennas are not feasible.

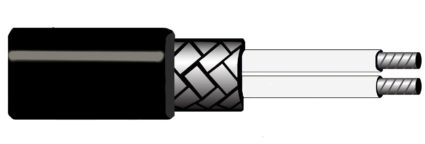

Twinaxial

Twinaxial

Also known as “Twinax,” these cables share the same structure as coaxial cables but have two central conductors instead of one. They are used for high-speed, short-range signaling applications, such as network hardware with SFP+ interfaces.

Triaxial

Semi-Rigid

With a PTFE-supported dielectric and a shield made of a solid conductor instead of stranded wires, semi-rigid coaxial cables offer better dielectric properties for enhanced performance at high frequencies. Compared to rigid cables, however, semi-rigid lines are limited in size and frequency transmission.

Rigid Line

Rigid coaxial cables contain two copper tubes and a PTFE dielectric buffer supported at both ends of the cable as well as at various intervals throughout which prevents bends. Ranging from ⅞-inch to 8³/₁₆-inch diameters, rigid lines are much bigger than semi-rigid cables and have the power capacities to operate TV and FM frequencies with multi-channel transmission.

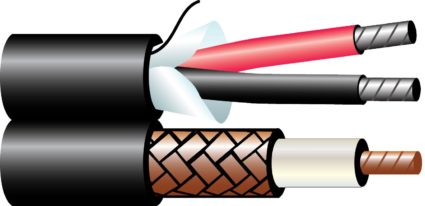

RG-6

RG-6

Made with either a copper clad steel (CCS) or bare solid copper (BC) center, RG-6 cables are probably the most common coax cable, as they are used to relay cable television signals. Derived from the WWII military-specification “Radio Guide,” they are available in four different application-specific variations:

- Plain — For standard indoor/outdoor house wiring

- Flooded — Contains an additional water-blocking gel for underground conduits

- Messenger — Contains a steel wire to bear the tension of the aerial drop of a utility pole

- Plenum — Surrounded by a Teflon-based outer jacket to meet the fire codes of ventilation ducts

Key Factors to Consider When Selecting a Cable

A coaxial cable’s radio guide (RG) number doesn’t always tell the whole story; there are a number of other factors to consider when selecting a cable for your unique application.

- Application — How will you be using your cable? Certain types are designated for specific applications, such as signal transmission for military operations, while others are designed for general use. Consider if your application will require short- or long-range transmission, as well as high or low frequencies.

- Impedance — Impedance refers to an electrical circuit’s resistance to alternating currents, expressed in ohms. Impedance should match throughout all components of a coaxial cable system to help prevent echoes, signal attenuation, and ghosting television images.

- Environment — Cables installed underground should pass through waterproof pipes to protect the jackets from liquid and vapor permeation. Users can also employ waterproof cords with self-amalgamating tape. To provide relief from sunlight and corrosive vapors, some manufacturers make use of hardened polyethylene cables, as well as tin and silver coatings.

- Working voltage and power rating — A coaxial cable’s voltage travels through the center wire or conductor. Each cable has a calculated maximum or “peak” voltage, which is then slightly reduced as a safety precaution.

- Signal loss at specific frequencies — Coaxial cable lines can be susceptible to signal loss at very high frequencies (VHF) and ultra-high (UHF) frequencies. Some manufacturers provide a foil or braided shield for VHF and UHF interference protection.

Why Choose Consolidated Electronic Wire & Cable?

With over 100 years of experience delivering industry-leading cable wire solutions, Consolidated Electronic Wire & Cable is proud to provide unmatched quality through our Total Quality Management (TQM) manufacturing system.

Conveniently located adjacent to Chicago’s O’Hare International Airport, consolidated offers a wide range of products such as electronic wire and cable, power and retractile cords, molded cable assemblies, and wiring harnesses, as well as short lead times. Consolidated can help you quickly fulfill your unique application requirements.

To learn more about how to select the right supplier for your job, download our free eBook, “Choosing a Wire & Cable Manufacturer for Your Application.”

() Quote Cart

() Quote Cart Twinaxial

Twinaxial

RG-6

RG-6