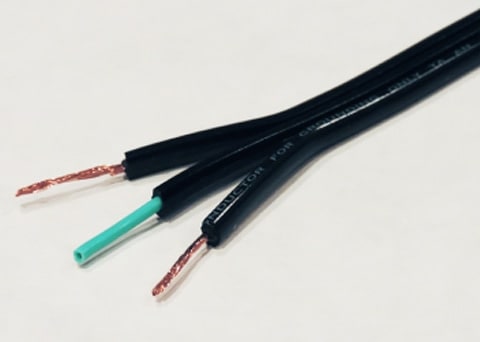

When a customer asked Consolidated to supply a galvanized steel braided coaxial cable for a remote control that was used in the agricultural industry, we immediately understood their need for a heavy duty, environmentally friendly, RG 62A/U product.

After reviewing the customer’s specification, Consolidated concluded that the coaxial cable with a galvanized wire braid was needed in order to successfully retrofit a number of their existing locations.

Consolidated was able to develop detailed specifications and drawings for a highly specialized RG 62A/U cable that met the customer’s construction and performance requirements.

The Consolidated custom coaxial cable met a variety of customer specifications, including tight tolerances of +/- .010”. Consolidated also performed tensile, AC HV, DC HV and flame tests. The highly specialized coaxial cable was delivered to the customer within 8 weeks.

To learn more about this project or for more information on our other products and services, please contact Consolidated Electronic Wire & Cable.

() Quote Cart

() Quote Cart